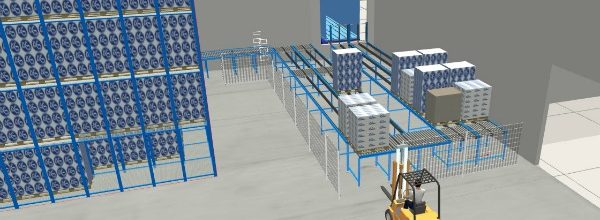

3D SIMULATION OF LOGISTICAL PROJECTS we no longer want to do without them

Once you have read this article, you will know why 3D simulations are becoming an increasingly essential part of the construction and furnishing of high-rise warehouses.

As a specialist in turnkey loading and unloading systems, we provide advice on the entire logistics process within warehouses. Our 3D simulation tool is proving to be of immeasurable value to us – and also for our customers.

This enables our clients to take a look in their own warehouse, although it is still to be built. Everything is depicted. The space, the racks, vehicles such as forklift trucks, narrow aisle trucks, roller conveyors, chain conveyors, right-angle transfer units and the automatic loading and unloading system. The software also knows how fast the vehicles move and how much space they need.

Once the basis is defined, we can let all kinds of scenarios loose on it. Our clients immediately see where logistics flows cross each other, where forklift trucks encounter problems and whether the space is used optimally.

The great befits of 3D simulation:

- It is difficult to test assumptions made beforehand that were based on static drawings. Thanks to the 3D simulations, we know at an early stage what is possible or not. Potential bottlenecks are immediately visible. That not only saves time, it also avoids (expensive) errors.

- We used to only make use of a CAD drawing. Experience has shown that they were interpreted differently by the various parties. With this simulation, everyone knows what is involved. In the initial stage, the system is of value for end customers and financial service providers who have to support the project. In the follow-up process, it is a perfect talking point for the suppliers.

- A 3D simulation provides the most reliable predictions relatively simply and a clear insight into for instance the maximum storage capacity, the number of outbound documents required or the personnel needs in all the different time periods.

The good thing is that – with mainly automated warehouses – we can use the same simulation after the building process for visualising the logistics process. We can connect the simulation to the final controls of the intra-logistics. That makes it even easier for operators to work with the system.

Clearly, we are very enthusiastic. It makes the concept phase easier and faster, and it gives so much more insight. Before you start to build, you already have the certainty that it will all work exactly as you envisaged.

Do you have any questions, remarks or would you like to know more about our systems? Then please get in touch. We will be happy to discuss this further with you.

e-mail: maas@a-service.nl

telephone: +31 (0)541 521206.