PAY PER PALLET | circular economy: intralogistics as a-service

I would like to talk about a business model that greatly interests us at Asbreuk Service, because it fits so well with our vision and the systems we supply.

I’m talking about the circular business model. In this model, products and materials are re-used and raw materials retain their value.

The most important principles

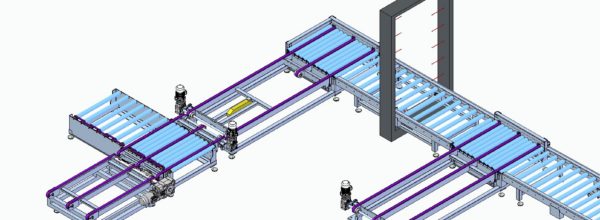

Customers no longer pay for a product, but for the service. This means you don’t buy a lamp or a fridge, but light or cooling. And in our case: you don’t buy automatic loading and unloading systems, roller conveyors, chain conveyors, right-angle transfers and turning modules, but pallet handling. As a customer, you’re no longer a product owner, but a service user. You specify what you need and the manufacturer supplies this, including the product or machine, service, energy consumption (if applicable) and all other relevant costs.

Ownership of the product remains with the manufacturer. After all, it is nothing more than the instrument used to deliver the service. Once the contract between the customer and producer comes to an end, the product is also returned. The manufacturer decides whether it can be used for a second cycle with another customer, or rebuilds it and uses the raw materials for new products.

A raw materials database must be set up to ensure that raw materials are re-used optimally. This contains information about the raw materials used in each product.

This business model resembles lease or rental, but is nevertheless fundamentally different. With lease or rental, you pay for a period of time, regardless of the performance delivered. When you choose the circular business model, you really pay for the performance itself.

Important issues

There are a number of important points in this business model. I will list these below.

As the performance determines the value, delivering good quality becomes extremely important for the manufacturer. Where the revenue model is now often based on discarding old products (buying new is cheaper than repairing), a long working life is crucially important in a circular economy. It simply costs too much to repeatedly send out a service technician. In addition, if the manufacturer must cover the energy costs, then it is safe to assume he will ensure the product operates as efficiently as possible. Manufacturers will devote even more attention to very low costs of ownership:

> even more robust systems

> greater modularity

> even more flexibility

> even easier to maintain

The term “new” will disappear. Suppliers can deploy systems that have previously been used. That’s no problem, because the manufacturer gives a functional guarantee.

The delivered performance must be measurable for the customer, but also for the supplier.

The funding requirements therefore shift; while the customer must now seek funding, it is the supplier who is obliged to do so with a circular model.

The supplier must always have unrestricted access to a system to ensure the functional guarantees can be met. This applies not just physically, but also online.

Ultimately, the customer-supplier relationship will change. It will be much more about partnership and co-operation.

Why this is interesting for customers

I believe that this business model will ultimately be cheaper for customers. Quality will play an even more decisive role, and more optimal use will be made of the product’s life cycle. This leads to less waste and inefficiency.

In addition, you know exactly what you’re getting as a customer. You are guaranteed a service for a predetermined period of time. This is the case regardless of maintenance, rising energy costs or other issues. These are no longer the responsibility of the customer, but of the manufacturer. As a customer you thus gain maximum flexibility while minimising risk.

Why this is interesting for Asbreuk Service

It is stated clearly in our policy plan: we want to make machinery we are proud of. This means it must be sturdy and strong, have a long life and require little maintenance. In addition, we supply our machines with decentralised control. This means they are very suitable for re-use.

We don’t like irregularities and surprises. We prevent these by maintaining control of as many things as possible. This means we prefer not to supply just systems, but to organise the complete process, from beginning to end. That also fits very well with this business model.

And finally: whichever way you look at it, raw materials will eventually run out. By re-using them as much as possible, we will do future generations a great favour. And as a company, we want to contribute to this.

Want to know more? Watch the TedX from Thomas Rau about this subject:

https://www.youtube.com/watch?v=zrb2v_f0ZYY

The circular economy is still in its infancy, but I find it interesting enough to think and to talk more about it. As such, I’d love to speak to companies who, just as I do, believe the idea is interesting and would like to share their thoughts about it.

e-mail: maas@a-service.nl

telephone: 0031 541 521 206.